One of the risks that we all must face as logisticians is in understanding and acknowledging the mission that our processes are designed to support within our respective organizations.

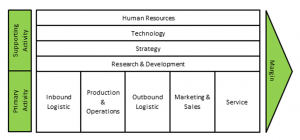

Many years ago, when I was in graduate school, I was exposed to the concept of Michael Porter’s Value Chain, where the primary activities of an organization or business are identified as activities that create value, while secondary activities are identified as those that support the organization.

Lately, I have been exposed to various different perspectives on what it means to manage material in DoD. As the saying goes, it matters where you sit. I have heard arguments for a strict compliance model with no value-creating business application (unique item management). I have also heard arguments for changing business models in order to make compliance easier. When put into the perspective of the old functional silos way of thinking, I suppose each of those arguments makes sense in their own self-contained world.

However, those silos of mentality are what we are trying to get away from. Ironically, one philosophy that could help is a return to fundamentals. Some modern business people have adopted a “first principles” concept from philosophy and physics, and that is exactly the kind of old-new thinking that is needed in order to effect the positive transformation that we seek in DoD.

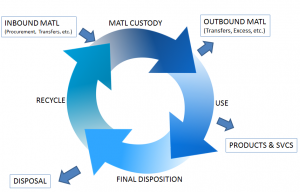

To apply the Michael Porter value chain model, we can argue that the fundamental reason to manage material is to create a product or deliver a service. I put together the above graph, adapted from various other models, to show how material moves in DoD, in most cases. The graph is divided into four quadrants or sections. The darker the arrow, in my estimation, the more critical that material management is to current or future operations. The darkest section (let’s call it quadrant 1) is where the bulk of the material management effort takes place.

So what does that mean? For the time being, just a point of discussion. The supporting activities in the DoD value chain that relate to material management need to consider where in the value chain their efforts are most effective. There is value in accounting, procurement, and information technology, but not at the cost of negatively impacting the missions that they support.